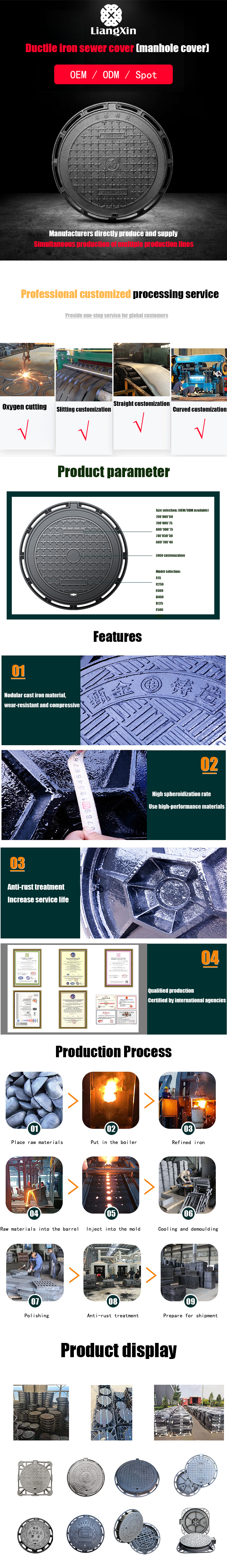

Product Description

The standard grade is c250, which means that the manhole cover can still be used normally when the center point is subjected to a force of 250 kN for five minutes. In the European EN124 standard, the pressure of the manhole cover is divided into the following six standards: A15, B125, C250, D400, E600, F900 Namely: the pressure is 1.5 tons, 12.5 tons, 25 tons, 40 tons, 60 tons and 90 tons. A load of 25 tons is considered heavy Generally used in urban non-main roads and small motor vehicle lanes. Under normal circumstances, it can be used on roads or parking lots where there are no large trucks. The installation of the ductile iron manhole cover is not completely completed after it is placed on the wall of the well. In addition to certain maintenance, it also needs to be reinforced. This is mainly to enhance its safety and durability, and to be better. To ensure the safety of pedestrians on the road and the quality of the manhole cover, how should it be reinforced? 1. Determine the height of the well masonry according to the design requirements of the reinforced well circle. Before installing the steel frame, the foundation pit should be cleaned up. The wall of the ductile iron manhole cover shall be densely poured with low-grade concrete and leveled. The steel frame should be processed into a square shape, which is consistent with the position of the well head when installed, and the protective layer of the steel bar should be ensured. 2. Well circle reinforcement and ductile iron manhole cover installation should be carried out before the construction of the asphalt surface layer, and the shape and size of the well circle reinforcement should be determined in accordance with the size of the manhole cover and the design requirements of the reinforced well circle. Generally, it is a square with the well head as the center, and a cutting machine is used to cut the seam to dig out the pavement structure within the reinforced range of the well circle. 3. The pre-embedded bolts can be installed at the same time as the well frame, or they can be positioned with a mold. The bolts should be placed vertically, and the nuts should be tightened before pouring the concrete to effectively connect them with the concrete and the reserved holes of the well frame.

| 承受应力水平 | C250型 | ||

| 最大承压轴承 | 25吨 | ||

| 生产标准和设备 | EN124(装配线设备和机械的生产) | ||

| 圆形(D*外径*高) | 方形(内径*外径*高) | ||

| 900 * 1000 *80毫米 | 600 * 700 *35毫米 | 800 * 1200 *40毫米 | 500 * 750 *40毫米 |

| 800 * 900 *80毫米 | 500 * 600 *35毫米 | 800 * 1000 *40毫米 | 500 * 500 *35毫米 |

| 800 * 900 *50毫米 | 400 * 500 *35毫米 | 750 * 1500 *35毫米 | 450 * 750 *35毫米 |

| 700 * 800 *50毫米 | 700 * 850 *70毫米 | 750 * 1000 *35毫米 | 400 * 600 *35毫米 |

| 700 * 800 *50毫米 | 700 * 800 *70毫米 | 800 * 800 *40毫米 | 400 * 400 *35毫米 |

| 680**780*50毫米 | 700 * 800 *65毫米 | 700 * 700 *35毫米 | 300 * 500 *35毫米 |

| 670 * 770 *35毫米 | 600 * 800 *40毫米 | 300 * 300 *35毫米 | |

| 600 * 600 *35毫米 | |||

| 承受应力水平 | C250型 | ||

| 最大承压轴承 | 25吨 | ||

| 生产标准和设备 | GB/T23858-2009(手工模具生产) | ||

| 圆形(内径*外径*高) | 方形(内径*外径*高) | ||

| 1000 * 1150 *80毫米 | 1500 * 1500 *60毫米 | 1000 * 100 *45毫米 | |

| 1200 * 1500 *50毫米 | 830 * 1650 *60毫米 | ||

| 1200 * 1200 *45毫米 | 1000 * 1500 *45毫米 | ||

| 1000 * 2000 *60毫米 | 1000 * 1200 *45毫米 | ||